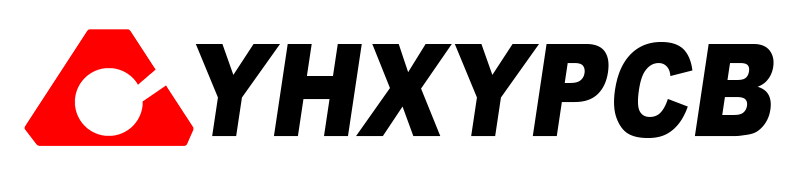

Rigid Flex PCB Manufacturing

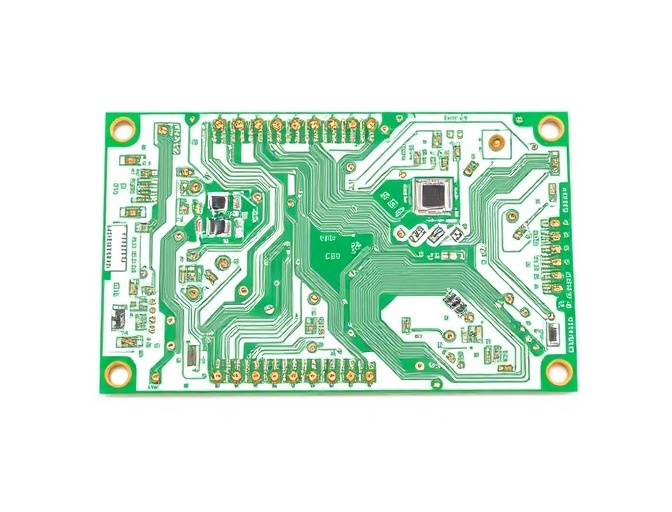

Rigid Flex PCBs combine the best features of both rigid and flexible circuit boards, creating a hybrid solution that offers exceptional reliability and design flexibility. These advanced circuits seamlessly integrate rigid PCB sections with flexible interconnections, enabling innovative three-dimensional electronic packaging solutions while maintaining superior electrical performance.

Manufacturing Process

Layer Stack-up

Rigid and flex material preparation

Integration

Rigid-flex lamination

Circuit Processing

Advanced PCB fabrication

Quality Control

Comprehensive testing

Technical Specifications

| Rigid Section Material | FR-4, High-Tg FR-4 |

| Flex Section Material | Polyimide (PI) |

| Layer Count | 2-14 layers (rigid), 1-4 layers (flex) |

| Minimum Flex Bend Radius | 1.5mm - 3mm |

Applications

Mobile Devices

Smartphones, tablets, and wearable technology

Automotive

Dashboard displays, control systems, and sensors

Industrial Equipment

High-reliability industrial controls and machinery

Advantages & Considerations

Advantages

- Combines rigid board stability with flex circuit versatility

- Eliminates connector and wire harness requirements

- Enhanced reliability through reduced interconnections

- Optimized 3D packaging solutions

Design Considerations

- Complex layer stack-up planning

- Transition zone design optimization

- Material thickness management

- Cost considerations for complex designs

Ready to Start Your Project?

Get expert support and competitive pricing for your multilayer PCB needs