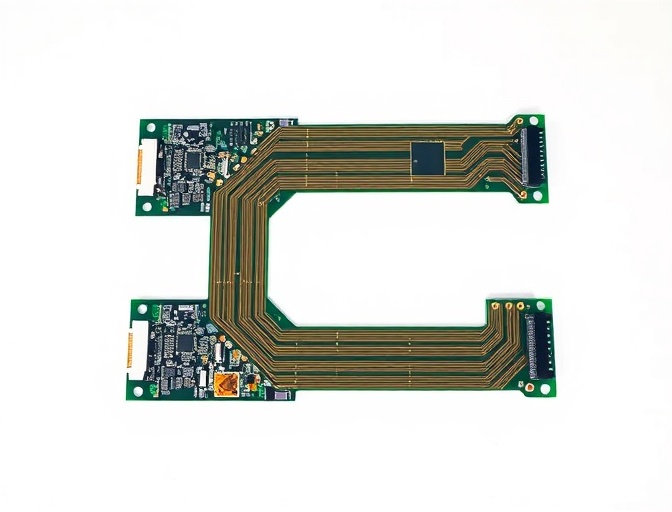

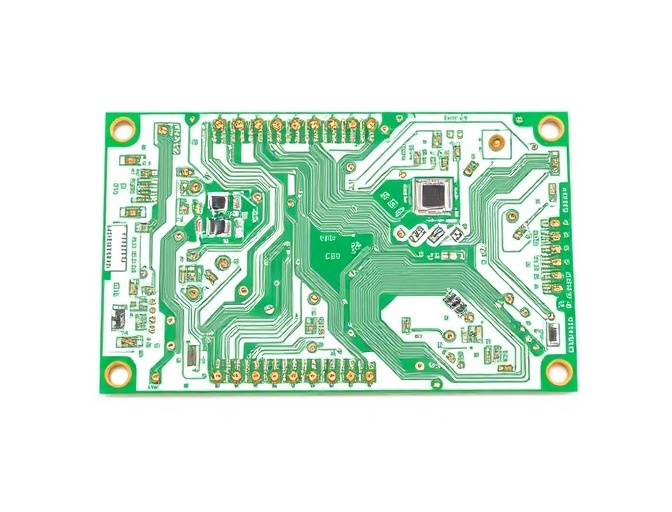

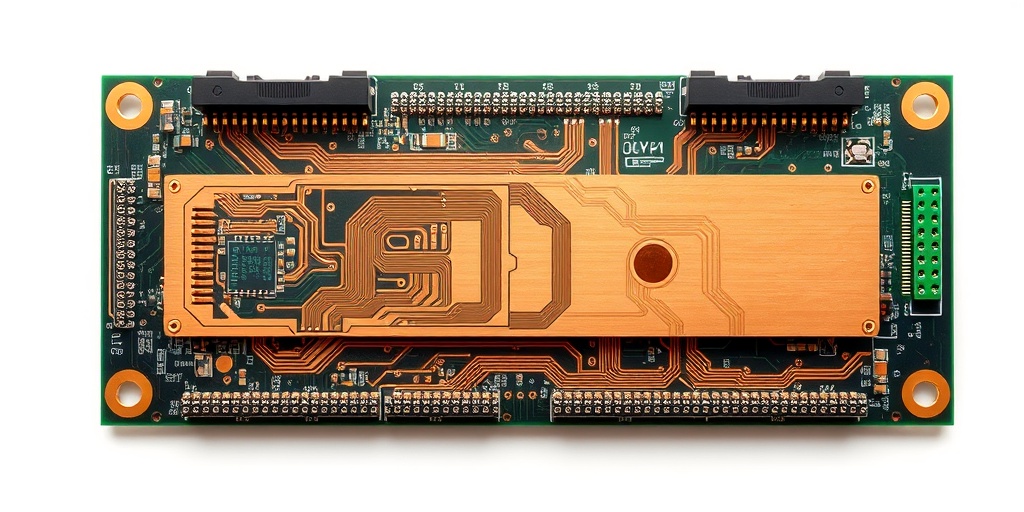

Multilayer PCB Manufacturing

Multilayer PCBs are sophisticated circuit boards consisting of three or more conductive layers, allowing for complex routing and higher component density. Our advanced manufacturing capabilities ensure precise layer alignment and superior quality for your high-performance electronic applications.

Manufacturing Process

Layer Preparation

Inner layer processing and imaging

Lamination

Layer bonding under pressure

Drilling

Through-hole and via creation

Finishing

Surface treatment and testing

Technical Specifications

| Layer Count | 4-28 layers |

| Board Thickness | 0.4mm - 3.2mm |

| Minimum Line Width | 3mil / 0.075mm |

| Minimum Spacing | 3mil / 0.075mm |

Applications

Consumer Electronics

Smartphones, tablets, laptops, and gaming devices

Industrial Control

Automation systems, robotics, and manufacturing equipment

Automotive

Vehicle control systems, infotainment, and safety features

Advantages & Considerations

Advantages

- Higher component density and complex routing capabilities

- Improved electromagnetic shielding

- Better signal integrity and power distribution

Design Considerations

- Layer stack-up planning is critical

- Impedance control requirements

- Thermal management considerations

Ready to Start Your Project?

Get expert support and competitive pricing for your multilayer PCB needs