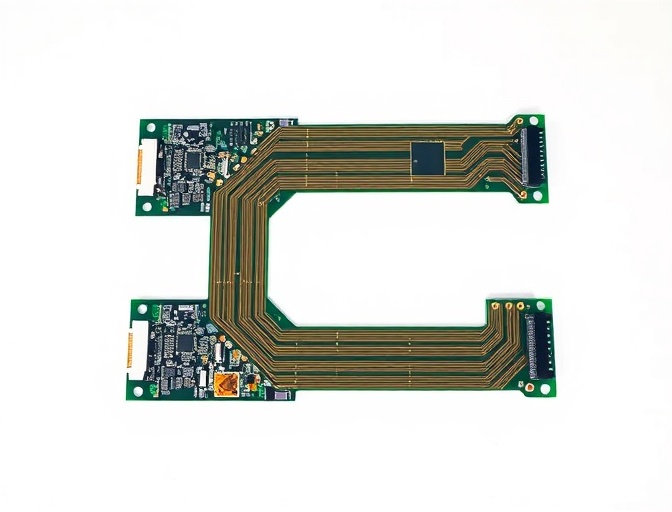

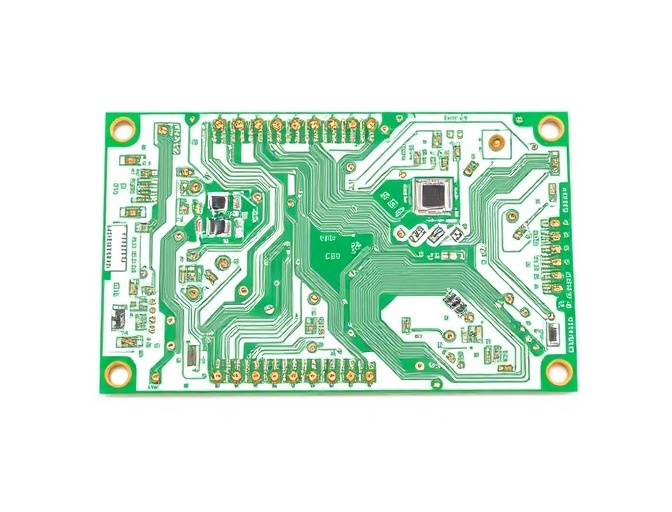

Flexible PCB Manufacturing

Flexible PCBs (also known as flex circuits) are advanced circuit boards built on flexible substrate materials, allowing them to bend, fold, and conform to unique spatial requirements. Our cutting-edge manufacturing processes ensure reliable, high-quality flexible circuits ideal for dynamic and space-constrained applications.

Manufacturing Process

Base Material

Polyimide film preparation

Circuit Formation

Copper pattern etching

Cover Layer

Protective layer application

Final Testing

Flexibility and electrical tests

Technical Specifications

| Material | Polyimide (PI), Polyester (PET) |

| Thickness | 0.1mm - 0.2mm |

| Minimum Bend Radius | 0.8mm - 1.5mm |

| Maximum Length | Up to 3000mm |

Applications

Digital Cameras

Compact cameras, lens assemblies, and optical devices

Medical Devices

Hearing aids, pacemakers, and diagnostic equipment

Aerospace

Satellites, aircraft systems, and space equipment

Advantages & Considerations

Advantages

- High flexibility and dynamic bending capability

- Significant space and weight reduction

- Excellent reliability in motion applications

Design Considerations

- Bend radius limitations

- Trace orientation in flex areas

- Material stress considerations

Ready to Start Your Project?

Get expert support and competitive pricing for your multilayer PCB needs