HDI PCB Manufacturing

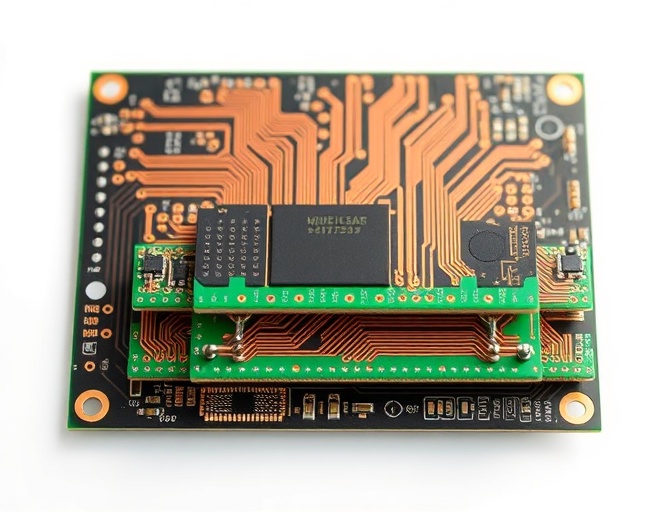

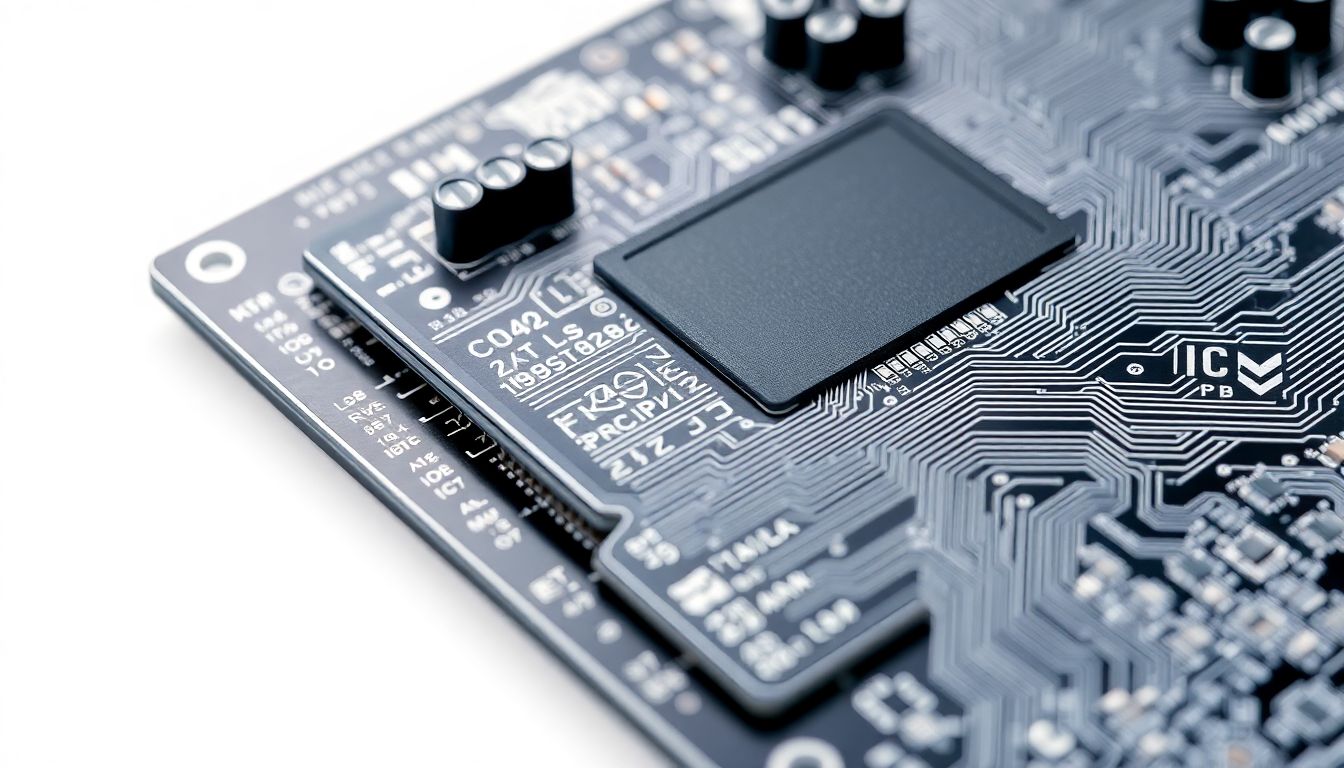

High Density Interconnect (HDI) PCBs represent the cutting edge of printed circuit board technology, featuring higher circuitry density and significantly more complex interconnections per unit area. These advanced boards utilize micro vias, buried vias, and blind vias to achieve maximum circuit density and superior electrical performance, making them ideal for modern compact electronic devices requiring high-speed signal transmission.

Manufacturing Process

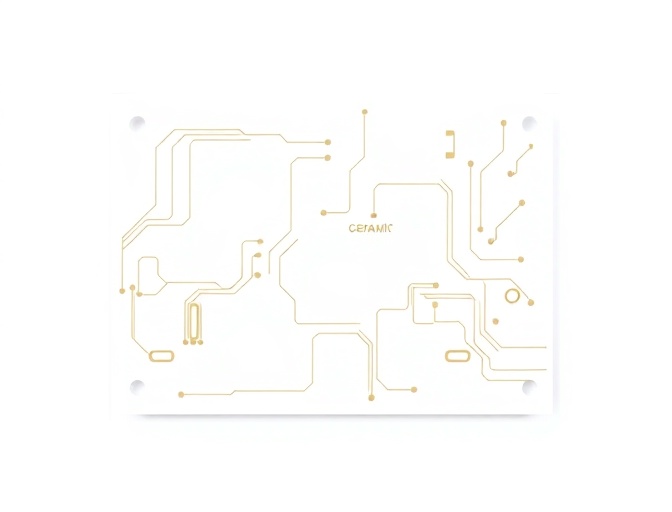

Material Selection

High-grade substrates

Laser Drilling

Micro via formation

Layer Stack-up

Sequential lamination

Quality Assurance

Performance validation

Technical Specifications

| Layer Count | 4-32 layers |

| Minimum Via Size | 0.075mm (3mil) |

| Line Width/Spacing | 0.050mm (2mil) |

| Aspect Ratio | Up to 12:1 |

Applications

Mobile Devices

Smartphones, tablets, wearables

Computing

Laptops, servers, networking

Digital Cameras

Professional and consumer cameras

Advantages & Considerations

Advantages

- Higher circuit density

- Reduced board size

- Better signal integrity

- Enhanced reliability

Design Considerations

- Advanced manufacturing process

- Higher production costs

- Complex design rules

- Stringent quality control

Ready to Start Your Project?

Get expert support and competitive pricing for your multilayer PCB needs