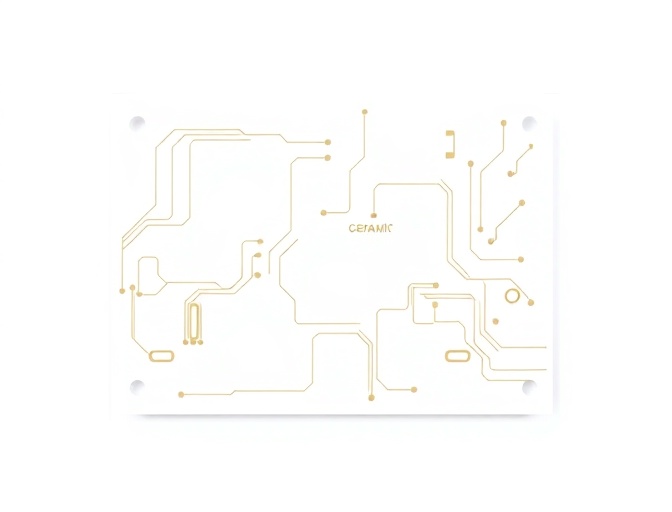

Ceramic PCB Manufacturing

Ceramic PCBs are advanced circuit boards manufactured using high-performance ceramic substrates. These specialized PCBs offer exceptional thermal conductivity, superior mechanical strength, and excellent electrical insulation properties. Ideal for high-temperature applications, power electronics, and LED lighting where traditional FR-4 PCBs cannot withstand extreme operating conditions or provide adequate heat dissipation.

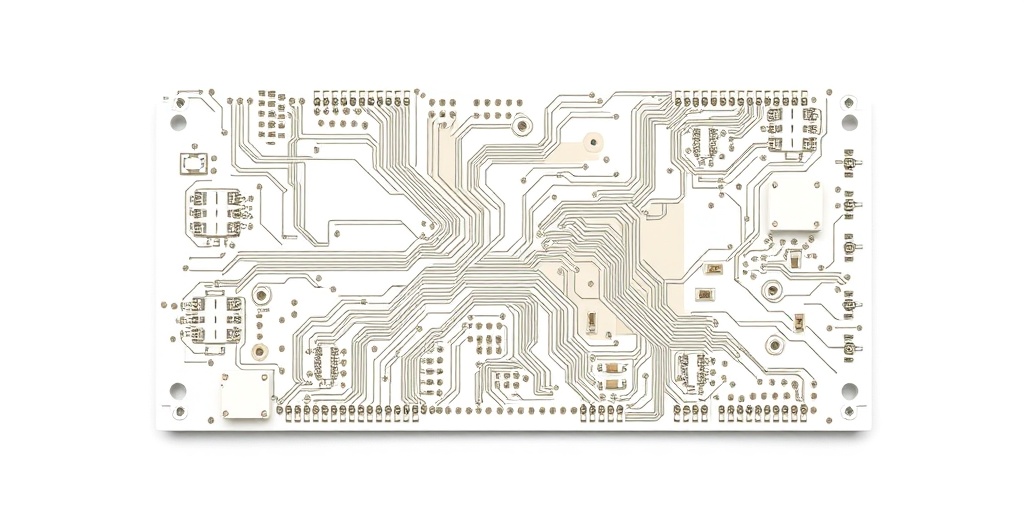

Manufacturing Process

Material Selection

Premium Rogers laminates

Precision Processing

Advanced impedance control

RF Testing

High-frequency verification

Quality Assurance

Performance validation

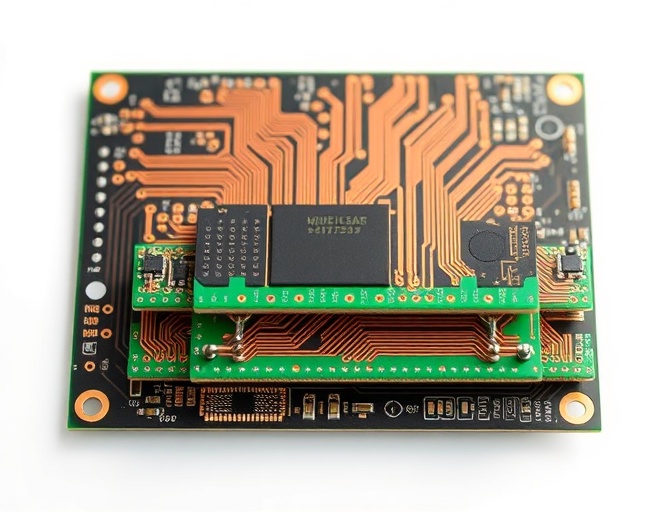

Technical Specifications

| Material Options | RO4350B, RO3003, RT/duroid 5880 |

| Frequency Range | DC to 77 GHz |

| Dk Range | 2.2 to 10.2 |

| Thickness Range | 0.101mm to 3.175mm |

Applications

RF/Microwave

Antennas, filters, and power amplifiers

Aerospace & Defense

Radar systems, communication equipment

Telecommunications

5G infrastructure, base stations

Advantages & Considerations

Advantages

- Superior high-frequency performance

- Excellent thermal stability

- Low dielectric loss

- Consistent electrical properties

Design Considerations

- Impedance control requirements

- Material handling sensitivity

- Higher material costs

- Specialized processing requirements

Ready to Start Your Project?

Get expert support and competitive pricing for your multilayer PCB needs